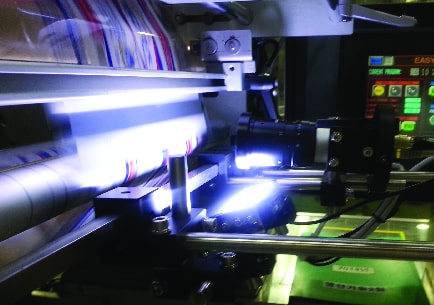

VIS(Vision Inspection System)

Vision inspection system is automated visual inspection equipment using a camera.

It is a system that can improve efficiency and provide objective and accurate quality control by automating the parts that were inspected manually with computer-based camera imaging technology. In particular, it is customized on-site by reflecting customer requirements. It can be applied to various fields such as manufacturing date inspection, packing defect inspection, foreign substance inspection, omission inspection, and product recognition and classification.

Inspection for expiration date

Inspection for expiration date of beverage and dairy products, pharmaceutical products

Inspection for packing defect

Inspection for packing defect of milk powder cans, containers, and packaged noodles

Inspection for foreign substances in products

Inspection for foreign substances in trays, containers, raw materials, and on product surfaces

Inspection for omission

Inspection for omissions of beverage, flakes and powder, straws and caps in cup coffee

Product recognition and classification

Heterogeneous defects inspection and product classification after product design recognition, Barcode inspection

Inspection for product appearance

Inspection for product label defect

Inspection for beverage product caps

Inspection for PET and glass bottle capping

Combined inspection system

Capping + Expiration date + Label + Liquid volume

* Detection performance may vary depending on the physical characteristics of the product

Computer-based high-performance system

- Implementing a multiprocessing method to perform complex inspections on highspeed lines simultaneously

- Up to 10 lines of simultaneous inspection with one system

Various additional functions

NSE's own food and drug testing library

Having diverse installation experience and technical skills

- Customizing production optimized for on-site lines with its own technical staff

- Applying and responding to the on-site design by customers

User-friendly, intuitive interface

- Graphical setup menu makes it easy for anyone to operate / intuitive main screen

Thorough follow-up management

- Continuous program update with own technical staff

- Online equipment inspection and real-time monitoring through the internet (when LAN network is supplied)

- Response visits within 24 hours in case of a problem

Diverse know-how based on long experience in the inspection equipment business

- More than 20 years of experience and know-how in operating inspection equipment business

- A large number of outstanding R&D personnel with extensive field experience

Business sustainability based on superior financial solvency

- Long-term stable customer response and serviceability